CCONORB Build Products Pvt Ltd

AAC Blocks Manufacturers and Suppliers :

CCONORB Build Products Pvt Ltd is Leading manufacturer and suppliers of AAC Blocks In Hyderabad,Autoclave Aerated Concrete, also known as AAC is a light-weight, high-insulating, durable building material and a latest technology developed in the Sweden in the mid-1920s by the Swedish architect and inventor Dr. Johan Axel Eriksson, at the Royal Institute of Technology.

AAC Blocks are manufactured through a reaction of aluminium on a proportionate blend of lime, cement and fly-ash. During this process, the hydrogen gas that escapes creates millions of tiny air cells, rendering AAC with a strong cellular structure. The product thus formed is not only light weight but also has higher compressive strength.

AAC blocks which we supply are of best quality, we offers incredible opportunities to increase building quality and at the same time it also helps us to reduce the costs of the construction site. if your looking for reliable aac blocks and aac bricks in Hyderabad and Vijaywada and Vishakapatnam Call us Now and place your order for aac Blocks and Bricks.

FEATURES OF AAC Blocks:

- HIGH STRENGTH

- LIGHT-WEIGHT

- ECO-FRIENDLY

- THERMAL INSULATION

- FIRE-RESISTANCE

- GOOD SOUND OBSERVATION

- EARTHQUAKE RESISTANCE

- GREEN-BUILDING CERTIFICATE ELIGIBILITY.

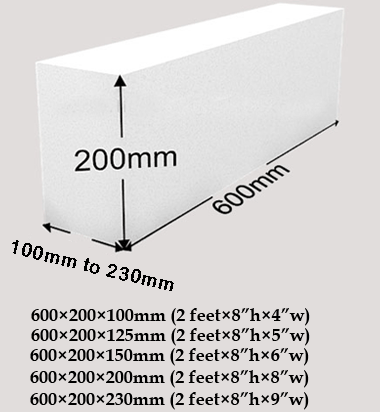

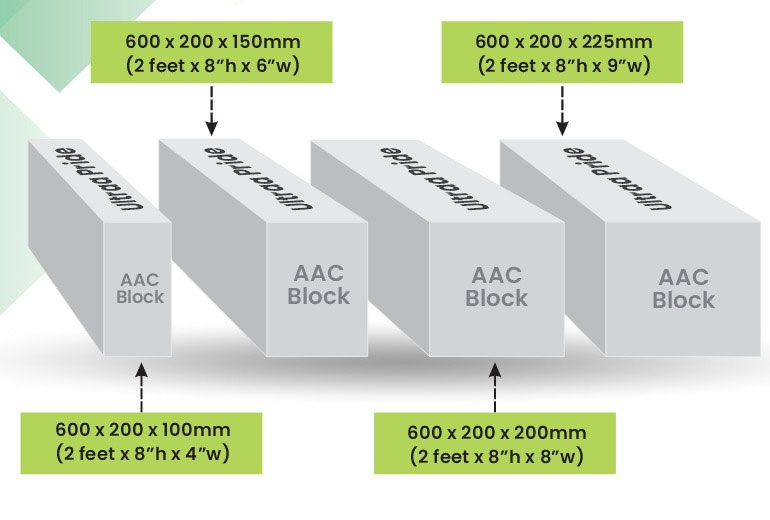

COMMON DIMENSIONS:

LENGTH(mm)

600(2 ft)

600(2 ft)

600(2 ft)

600(2 ft)

600(2 ft)

HEIGHT(mm)

200 (8")

200 (8")

200 (8")

200(8")

200(8")

THICKNESS(mm)

100 (4")

125 (5")

150 (6')

200 (8")

230 (9")

All other Block Dimensions like 50mm, 75mm upto 300mm will be supplied in special order.

ADVANTAGES OF AAC BLOCKS:

AAC has been produced for more than 70 years, and it offers several significant advantages over other cement construction materials, one of the most important being its lower environmental impact.

- Improved thermal efficiency reduces the heating and cooling load in buildings.

- Porous structure allows for superior fire resistance.

- Workability allows accurate cutting, which minimizes the generation of solid waste during use.

- Resource efficiency gives it lower environmental impact in all phases of its life cycle, from processing of raw materials to the disposal of waste.

- Light weight saves cost & energy in transportation, labor expenses, and increases chances of survival during seismic activity.

- Larger size blocks leads to faster masonry work.

BENEFITS OF AAC:

- FIRE-RESISTANCE: A wall of AAC has a 4-6 hour fire resistance depending on the thickness of the wall.

- ENERGY SAVINGS: AAC block has excellent thermal insulation properties. It greatly reducts energy consumption of the heating and cooling appliances.

- WEATHER RESISTANCE: AAC can be used in all climates and will not deteriorate in extreme heat or cold conditions.

- SOUND RESISTANCE: AAC is used extensively as freeway sound barriers and fire walls all over the world.

- ECO-FRIENDLY: AAC consumes less energy to make, less to transport and contains no toxic gases.

- PEST RESISTANCE: As the blocks are made of inorganic materials, the pest resistant properties of AAC keeps termites away, avoiding damages and losses.

- LIGHTWEIGHT: AAC blocks are approximately 1/3rd the weight of conventional clay bricks, greatly reducing dead weight of the structure. Steel can be reduced by 15% and cement by 10% when AAC blocks are used for construction.

- EARTH QUAKE RESISTANCE: The manufacturing process gives the blocks commendable strength, maintaining its light weight property. This make the buildings earthquake resistance and gives it a longer life.

- RAPID CONSTRUCTION: Time consumed when buildings are constructed with AAC blocks due to large size and light-weight and easy work ability.

- WATER SAVER: For the curing process of AAC blocks walls, there is no need to water the blocks, only the mortar joints need to be cured which reduces the water consumption.

TECHNICAL SPECIFICATIONS:

PROPERTIES |

SPECIFICATIONS |

SIZE |

600mmX200mmX100-300mm |

COMPRESSIVE STRENGTH |

4.0-5.0 N/mm2 |

DRY DENSITY |

550-650 kg/m3(oven dry) |

FIRE RESISTANCE |

4-6 Hours depending on thicknesss |

SOUND REDUCTION INDEX(dB) |

45 dB for 200mm thick wall |

THERMAL CONDUCTIVITY |

0.16 (k) W/m deg.C |

COLOUR AVAILABILITY |

Greyish White |

FINISHES:

There are a variety of compatible finish materials now-a-days in a market that can be applied to AAC. Light-weight STUCCO's that are vapour permeable, yet hydrophobic so as not to allow water penetration, are applied as a single base coat followed by a colour or texture coat for AAC. Other exterior materials, for instance, brick , stone veneer, ceramic or porcelain tile cladding, marble and granite cladding etc., can be attached to AAC walls. Specialized marble aggregate finishes have been used in a one-coat application.

For interiors, a number of fine plaster products are available in the market whose characteristics are compatible with AAC. They are easy for us to use in a hand towelled or spray application, followed by a texture/veneer coat.

AAC BLOCKS MAJOR APPLICATION:

- Residential Buildings

- Hospitals

- Commercial Buildings

- Educational Institutions

- Industrial Buildings

- Hotels

- Godowns & Cold storages